Laser welding: Process, advantages, methods & areas of application

Laser welding is characterized by its narrow weld seams and the high speed at which it can be carried out. The welding machine can also be used without shielding gas. This makes it particularly suitable for all workpieces where it is important to keep the thermal load low in order to avoid warping.

The laser beam is directed at the material with a thickness of a few tenths of a millimeter. The energy is absorbed there and leads to strong heating. The weld seam is very narrow due to the concentrated energy, so that it cools down again very quickly. This makes it very hard and favors a high working speed. Also, no filler material is introduced. The process can be used with many different materials, including metals as well as plastics.

Table of contents

Estimated reading time: 7 minutes

How does the laser welding process work?

The laser is directed at the workpiece without touching it, without an additive. The welding depth is determined by the parameters of the laser and its position in relation to the surface of the workpiece.

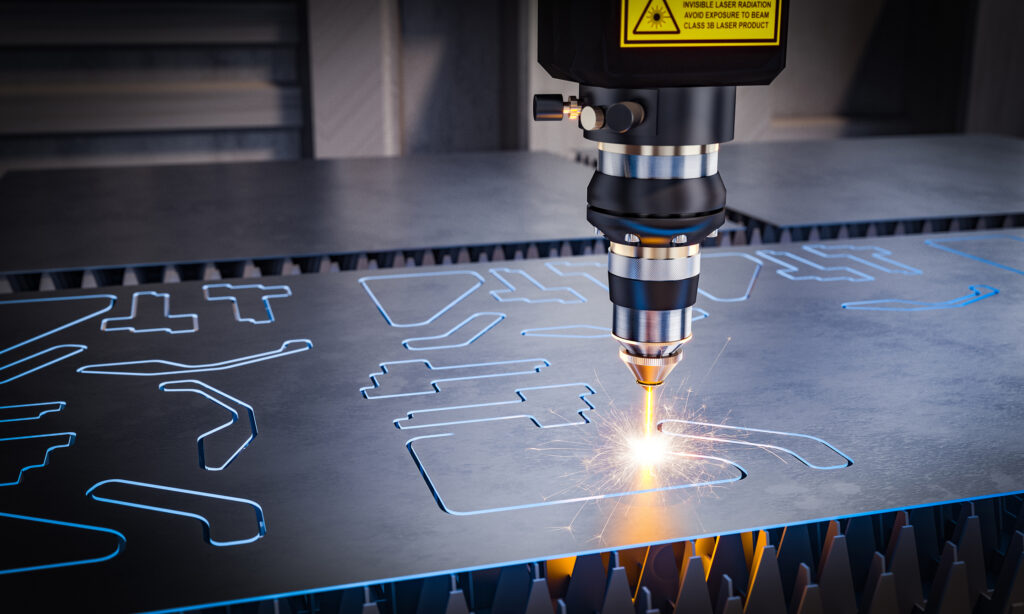

Focusing optics are used to bundle the laser beam to a diameter of 0.2 to 0.3 mm. The resulting focal spot on the workpiece allows the material to be melted very quickly and partially vaporized.

In this way, a vapor channel is formed in the workpiece, around which the melting zone is located. The material melts very quickly and then hardens again very quickly.

Which are advantages of laser welding?

The laser can be used to join almost all plastics and almost all metals with a slim seam and smooth surface. This means that aluminum welding is also possible as a process. The process is completely contact-free in all cases and with all materials. There is also no need to prepare the weld seam. The process can be carried out at a high speed, whereby the best quality weld seams are achieved in comparison.

The heat input into the workpiece is low, so that no distortion occurs. No force is required on the workpiece, for example by applying pressure. The accuracy is only plus/minus 0.01 mm. This means that even very thin sheets can be processed. There is also usually no need for reworking. This process can also be used to work in difficult areas.

In which applications is laser welding used?

When it comes to the precise and fast joining of metal or plastic components, laser welding is the solution. This is particularly the case here:

- For the production of transmission parts in the truck and car industry

- For the production of sensor housings that are also gas-tight

- In the extraction of stones in medicine

- The manufacture of pacemakers

- For the production of pole tubes

- The manufacture of motor housings

- For the internal gearing of cranks

- The assembly of sheet metal assemblies

- The production of roller levers

- The manufacture of EGR valves

How does the laser welding process work?

A number of different processes are used for laser welding. Each has its own advantages, making it more suitable for certain tasks.

Spot and depth welding

With spot and depth welding, sheets can be joined together using very small welding spots with a diameter of less than 0.1 mm. The laser source is selected according to the required strength.

Seams can also be welded using several welding points in pulse mode. Even this is also very fast, as the energy input is highly concentrated and therefore the melting and subsequent re-solidification takes very little time.

If a great depth is required for welding, deep laser welding is the best solution. This works with a power density that corresponds to 1 megawatt per square centimeter. This results in very rapid melting at depth without a very high heat input.

Scanner welding

In scanner welding, a robot with a scanner and a fiber laser is used. The scanner detects where welding is taking place and the fiber laser does its work. This is done automatically, very quickly and very precisely. Together, this also means that the process is very cost-effective.

Welding plastics and pipes

When plastics are welded, this usually involves two different thermoplastics. These are overlapped and the laser beam penetrates the material of the upper part. This happens almost unhindered. As a result, the lower part absorbs the mass of the energy and develops the corresponding heat. This heat is also transferred to the upper part so that both plastics melt and a joint is created.

If pipes are joined using the laser welding process, special machines are used. These are designed to handle even complex welding tasks. This allows a high degree of automation, which in turn is advantageous for the process speed. Up to 60 meters per minute can be welded without any heat distortion.

Which influence does the laser have?

Laser welding is actually a little more expensive than other processes. Nevertheless, it is always used where other processes are not suitable. However, with new developments in laser technology, the cost factor is being reduced more and more.

CO2 laser welding

In most cases, a CO2 laser is used for laser welding. A carbon dioxide gas is used to generate a specific wavelength for the laser. This wavelength is in the infrared range and is designed to be absorbed by the workpieces.

The advantage here is that a CO2 laser can produce a comparatively inexpensive bond with many different materials. The disadvantage is that it does not allow the same precision in the application that is possible with other lasers.

Other lasers are superior, especially when it comes to very small and complicated weld seams. There is also a risk in using the CO2 laser. It can be damaged by water vapor. It is therefore always important to keep the welding area absolutely dry during work.

Fiber laser welding

Fiber laser welding is still a relatively new process. The laser beam is generated using a fiber optic cable. This makes this laser much more precise than a CO2 laser. This also means that it is suitable for small and complicated weld seams. The disadvantage is that it is more expensive. There is also a risk of the laser being damaged by dust or other impurities that may be present.

YAG laser welding

Laser welding with a YAG laser is the oldest of the various laser welding methods. A neodymium-doped yttrium-aluminum-garnet crystal is used to generate a laser beam. This is where the name Nd:YAG laser comes from. These are also more expensive than a fiber laser, but not as precise.

More about welding: